Telescopic Spring Covers

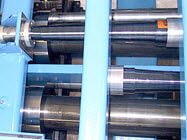

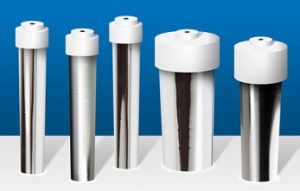

CQM designs and manufactures a complete line of telescopic spring steel covers for a wide range of applications.

CQM’s engineers are committed to understanding each customer’s specific application requirements to create custom conical spring covers based on your specifications. CQM utilizes special manufacturing techniques and carefully selected materials to provide the best protection for your equipment. CQM is a world-class manufacturer of conical spring covers and can complete orders ranging in size from large to one-piece prototypes. Please contact us for more information about spiral spring cover options.

Telescopic Springs Steel Cover Details

Materials

Standard telescopic spring covers are made from high-quality blue spring steel strip (55-58 Rockwell) with rounded edges. Strength up to 1800 N/m2.

If regularly used with coolants of high water content, we recommend spring covers be made of stainless strip steel. However, due to the properties of this material, the spring force of these springs is less so that they cannot be made in all sizes. Please contact us for details.

Installation

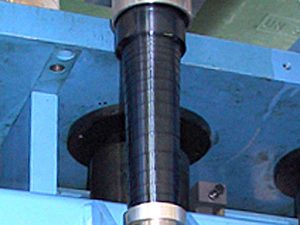

Telescopic spring covers can be installed either horizontally or vertically. To avoid “sagging”, telescopic springs designed for horizontal use have a larger overlap of coils than those designed for vertical use, and their larger diameter should be located where the majority of chips will be encountered.

Due to their high initial torque, telescopic spring covers designed for vertical mounting always require a longer extension than horizontal spring steel covers, and their larger diameter should be at the top.

Flanges

As a spiral spring cover manufacturer, CQM recommends the use of collar and pilot flanges on each end of a telescoping spring cover to allow for the spring to turn. The telescopic spring must be able to move freely to ensure maximum life and must NOT under any circumstances be fixed (by means of screws or rivets).

Operating Conditions

CQM designs telescopic spring covers to allow for traveling speeds up to 40m/min. Telescopic springs find optimum operating conditions in an oily environment. They are not suitable for use where fine particles or dust are encountered. In the latter case, we recommend the use of bellows.

Maintenance

Regular maintenance of conical spring steel covers is indispensable. Depending on the amount of soiling, the springs should be cleaned daily or weekly, followed by the application of a thin oil film in accordance with our maintenance instructions. A special spray can be supplied by us to ensure the longest life of your telescopic spring covers. Never grease telescopic springs!